Mechanization in large-scale agricultural production

Mechanization is essential in large-scale agricultural production. At THACO AGRI’s complexes, various machines and equipment have been used to enhance productivity, reduce labor and investment costs, bringing high production efficiency.

In Snoul, on over 10,000 hectares, the complex plans specialized areas for bananas, rubber, and forest crops, semi-intensive cattle breeding and mangoes, and freshwater fish breeding. Here, the mechanization has been gradually integrated into the agricultural production, serving all stages from land preparation, canal digging, roadworks to cultivation, tending or harvesting bananas and grass, or prevent pest, etc. Manual works are being replaced by machinery and equipment to increase productivity and reduce labor.

According to Mr. Truong Thanh Nghia, the Mechanical Manager at Snoul, the complex has been equipped with more than 40 vehicles, e.g. excavators, bulldozers, cattle feed spreaders, large pesticide sprayers, grass harvesters, tractors; 2 water trucks for infrastructure construction and firefighting when necessary; 1 grinder and 1 food mixer; and 5,510 banana pulley frames.

In Koun Mom, on an area of over 33,000 hectares, the complex divides into specialized areas for bananas, pineapples, rubber, and forest crops; semi-intensive cattle farming and mangoes. The production of organic microbial fertilizer and agricultural supplies apply mechanization methods with a suitable roadmap, providing high-quality organic products for both domestic and export markets.

Mr. Nguyen Khac Thien, the Equipment Management and Operation Manager at Koun Mom Complex stated, "The complex currently has 153 vehicles for growing crops and livestock, such as tractors, feed grinders, pesticide sprayers, harvesters; 38 vehicles to take care of the current transport and water infrastructure projects (excavators, dump trucks, rollers, water-spraying trucks, etc.), a concrete mixing center for transportation and water infrastructure projects; and roughly 13,200 meters of banana pulleys. The complex is expected to purchase more machinery and equipment to serve production and livestock, like spraying machines, row plowers, fertilizer and quicklime spreaders, corn harvesters, feed processors, and bedding production machines; and to build the first fruit processing center for mangoes, pineapples, and lychees at Koun Mom complex."

With the current operational scale at the complexes, the increased mechanization content in agricultural production has led to shorter cycles in crop cultivation and harvest, more cost efficiency, increased productivity, enhanced economic efficiency, and especially improved post-harvest loss reduction.

New posts

-

Following the strong digital transformation trend across many industries, Ia Puch Cattle Farm has pr...

Following the strong digital transformation trend across many industries, Ia Puch Cattle Farm has pr...

-

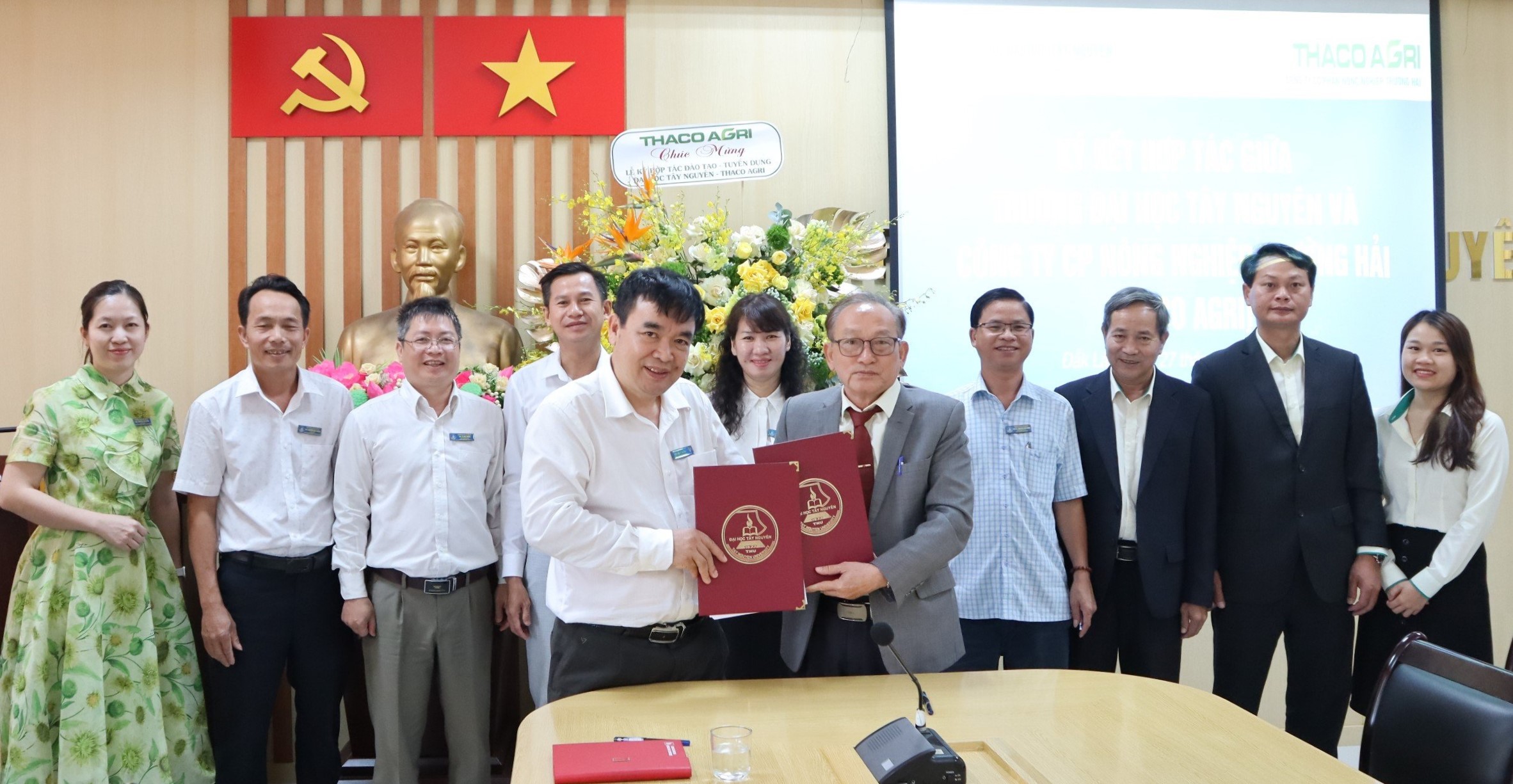

Recently, THACO AGRI has cooperated with different Vietnamese and foreign universities to recruit ta...

Recently, THACO AGRI has cooperated with different Vietnamese and foreign universities to recruit ta...

-

After the fruit care period, Cao Nguyen Durian Enterprise begins its durian season with positive pro...

Image gallery

Video gallery

THACO AGRI - A MEMBER OF THACO GROUP

The film introduces an overview of THACO AGRI.

DEVELOPING FRUIT TREES IN CAMBODIA

Cambodia encourages enterprises to develop large-scale fruit trees for export.

AMBITIONS OF THE LARGEST BANANA EXPORTER IN SOUTHEAST ASIA

THACO AGRI is not only one of the leaders but also the largest Cavendish banana tree grower in Cambodia.